What Materials Are Used in Chip Repairs? A Deep Dive

An Introduction to Chip Repairs

In the realm of automotive and electronic maintenance, chip repairs are a common necessity. Whether it's repairing a windshield or fixing a microchip, the materials used in these repairs are crucial to ensuring durability and effectiveness. This blog post will explore the various materials commonly used in chip repairs, shedding light on their specific applications and benefits.

Materials Used in Windshield Chip Repairs

Windshield chips are a frequent occurrence for many vehicle owners. The primary material used in repairing these chips is resin. Resin is favored for its clear, adhesive properties that mimic the appearance and strength of glass. It fills in the chip or crack, preventing it from spreading and maintaining the structural integrity of the windshield.

There are different types of resin, including thin resin for small chips and thicker resin for larger cracks. The choice depends on the size and severity of the damage. The curing process, often aided by UV light, solidifies the resin, creating a strong bond with the glass.

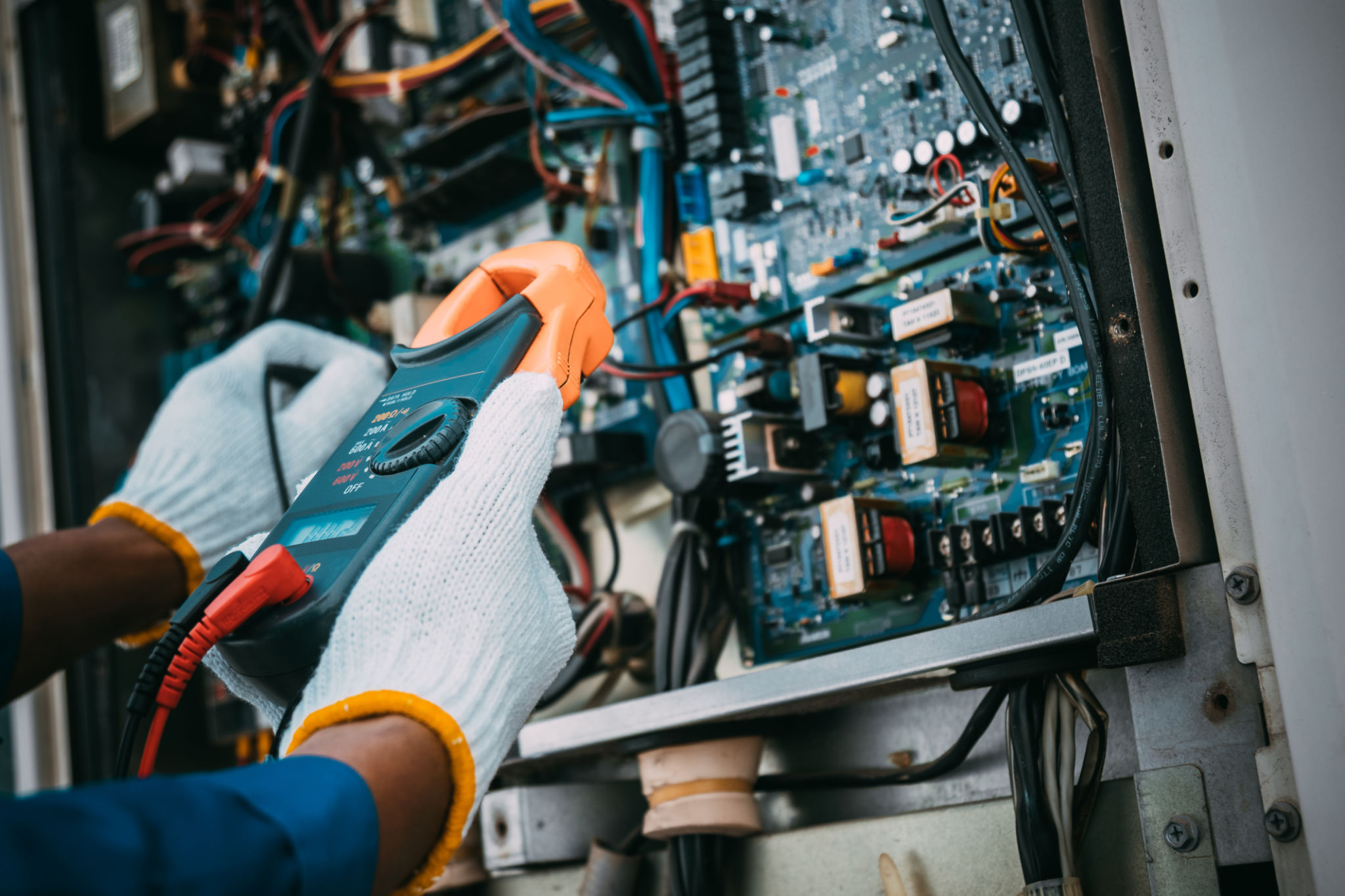

Materials Used in Electronic Chip Repairs

When it comes to electronic chip repairs, the materials differ significantly from those used in automotive applications. One of the most commonly used materials is soldering alloy, typically composed of tin and lead. This alloy melts at low temperatures, making it ideal for repairing delicate electronic components without damaging them.

Another essential material is epoxy resin. This type of resin is used to encapsulate and protect repaired areas on a circuit board. It provides insulation and protection against environmental factors such as moisture and dust, ensuring the longevity of the repair.

The Role of Conductive Materials

In electronic repairs, conductive materials play a crucial role. Conductive inks and adhesives are often employed to establish electrical connections between components. These materials contain conductive particles, such as silver or carbon, which allow electricity to flow between repaired areas efficiently.

The use of conductive materials is particularly important when repairing damaged traces on circuit boards. They can restore functionality by reconnecting broken paths, ensuring that the device operates as intended.

Environmental Considerations

As with many repair processes, environmental considerations are becoming increasingly important. The use of environmentally friendly materials in chip repairs is gaining traction. For instance, lead-free soldering alloys are now widely used to reduce toxic waste. Similarly, eco-friendly resins made from sustainable resources are being developed to minimize environmental impact.

These innovations not only benefit the planet but also enhance the safety of repair technicians by reducing exposure to hazardous substances.

Conclusion: The Future of Chip Repair Materials

The materials used in chip repairs are constantly evolving. Innovations in material science continue to improve the effectiveness, safety, and sustainability of these repairs. As technology advances, we can expect even more efficient and environmentally friendly solutions to emerge.

Understanding these materials and their applications not only benefits professionals in the field but also empowers consumers to make informed decisions about maintaining their vehicles and electronic devices.